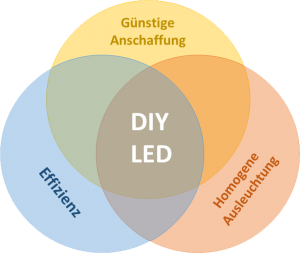

Building plant lights yourself - DIY LED - continues to be in vogue. Why are do-it-yourself LEDs so attractive for plant lighting in private indoor cultivation? When it comes to lighting for plants, there are three key requirements that have long contradicted each other:

- Low acquisition costs, as many photons per Euro as possible

- An even distribution of light over the entire cultivation area. This means the most homogeneous PPFD values.

- Efficiency. As many photons as possible per kilowatt hour of electrical energy.

High intensity discharge lamps - NDL/HPS & Co.

Until a few years ago, the most popular light sources for indoor plant lighting were gas discharge lamps (NDL, MDL, etc.), as they promised a high light yield at low investment costs.

But even if we ignore the heat problem of this type of lamp, there is a big problem with the even distribution of light. Reflectors and spreaders can only avoid so-called hotspots at the expense of efficiency, while the illumination at the edges is greatly reduced.

But these are already quite old-fashioned light sources, after all we live in the age of LEDs! Their only disadvantage is that they are comparatively expensive...

DIY - DIY LED

But with the light emitting diodes a cheap solution can be realized, if you have a little bit of craftsmanship. For DIY LED plant lamps there are different approaches, which we will briefly introduce in the following:

E27 panel as plant lighting

The absolute entry-level class in the DIY sector is E27 lamps, which can be purchased in any DIY store. As they can be supplied directly with mains voltage on the E27 base, they are considered a very cost-effective alternative to the other DIY LED options that require a special power supply unit. The components are extremely easy to get and cheap. Some simple LED bulbs with 7 watts are available for only 1 €.

As inviting as this concept is, it also has some disadvantages.

- Headroom: The LED bulb itself is already relatively long, plus the base and wiring, so you have to reckon with about 20 cm height. This is often wasted space in narrow grow boxes.

- Efficiency: Most manufacturers do not prioritise this. 130-140 lm/W is the most that can be expected, average products deliver about 100 lm/W.

- Lifespan: Due to the shape of the housing, which is based on the incandescent lamp, the heat dissipation is often insufficient. Therefore, usually only 20,000 hours can be expected.

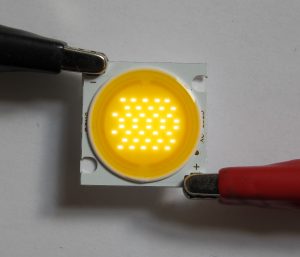

COBs

For a long time, the most popular DIY LED solutions were COBs - chips on board - which have the advantage of simpler wiring compared to the equally efficient high-power LEDs. Here, however, photons are generated centrally again and must be distributed by suitable optics, which is basically at the expense of efficiency. The concentrated power of the COBs on a very small area also requires complex cooling solutions.

The most popular COBs for indoor plant lighting have long been the Cree CXB3590, which can run up to 130W. In order to achieve an acceptable light output of approx. 2.3 µmol/J, this LED chip is supplied with a low current and then needs approx. 50W.

LED strip

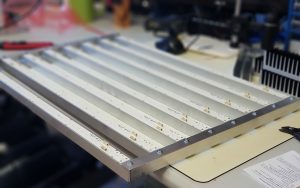

In the meantime the hobbyist scene has developed further. In recent years, more and more affordable Mid Power LEDs have been launched on the market, which are more efficient and, above all, provide better light distribution. To achieve this, as many dedicated LEDs as possible are distributed over a large area to achieve a very even illumination.

In the hobby sector, LED engines are mostly used for mid-power solutions, which are offered by the major manufacturers for retrofit solutions. These strips - also called Strips or Stripes - are intended as a replacement for neon tubes. Several of them can be combined to form a panel, which usually only requires plug connections. Even though mid power chips usually don't generate much waste heat, a simple heat sink is recommended for efficient and reliable operation. Resourceful hobbyists build a grid from simple U-profiles onto which the strips are mounted.

Disadvantages of LED strips

This is an efficient and, above all, inexpensive way to build efficient plant lighting. However, the Stripes also have disadvantages.

Basically, the LED strips are not designed for plant lighting - to achieve the required intensity, a large number of strips must usually be combined - a tangled mess of cables is inevitable.

In addition, the strips are often not ideal for heat dissipation, as the cheaper variants are usually made of FR4, a synthetic resin. Higher-quality stripes rely on aluminium-core PCBs, which distribute and dissipate heat well.

But what can actually become a problem for DIY LED projects are the mounting options. All that is left for the hobbyist is double-sided adhesive tape, which further impairs heat conduction and in the worst case even loses its adhesion due to thermal stress.

Crescience LED Stripes: The FLUXstrips and APEXstrips

Our FLUXstrips and APEXstrips have been developed to simplify the individual construction of strip panels. The modular system is based on 48 cm long LED strips, which are offered in many horticulture-specific light colours and wavelengths. The strips are made of thermally conductive aluminium and have holes for mounting on standard 20 mm pitch grooved profiles.

LED Engines

One possible solution to achieve high performance without sacrificing efficiency and illumination are Grow LED Engines. These modules are available in numerous variants. Mostly they are equipped with numerous mid-power LEDs, such as the efficient Samsung LM301B or the newer LM301H.

Crescience has the FLUXengine was developed as a compact LED board to establish a DIY friendly solution to build high efficiency grow LEDs by yourself.

For someone who values the highest energy efficiency in the lighting system, these LED engines are ideal. The FLUXengine can be screwed onto standard slot profiles, which in most cases even saves the purchase of a separate heat sink. With a solid, three millimetre thick aluminium PCB, the FLUXengine is optimised for best heat dissipation. The dimensions are based on the common dimensions for furniture and grow boxes, so that the ideal lighting can be constructed for any surface.

The special feature of this LED module is that a large number of LED chips are installed on the surface, which means that the FLUXengine achieves an extraordinarily high luminous efficacy at low load (700-2000 mA of max. 4000 mA).

Crescience also provides reference designs and comprehensive documentation for do-it-yourself construction. However, we would like to point out that do-it-yourself plant lighting is only recommended for qualified professionals.

LED Boards - FLUXshields

LED Boards like the FLUXshield are becoming increasingly popular. Because a large part of the tinkering is omitted here, these large LED modules are ideally suited for DIY Grow LEDs. The LED board can be connected directly to the power supply, which is then equipped with a Schuko power cable.

For larger areas, several of these boards can be connected on a frame of grooved profiles to achieve the required performance. This can be done very quickly and easily. Therefore, LED boards, especially FLUXshields are the first choice when large areas are to be illuminated in a cost-optimized and efficient way.

Conclusion: DIY LED for plant lighting

We hope you enjoyed this article and that it provides an informative overview of DIY plant lighting options. DIY LEDs for plant lighting are an excellent alternative to ready-made products, as a better result can be achieved at a lower cost. The only disadvantage is that you need to be an expert to do the wiring correctly. If you have any questions about the topic or our products, please do not hesitate to contact us. Contact record!